描述

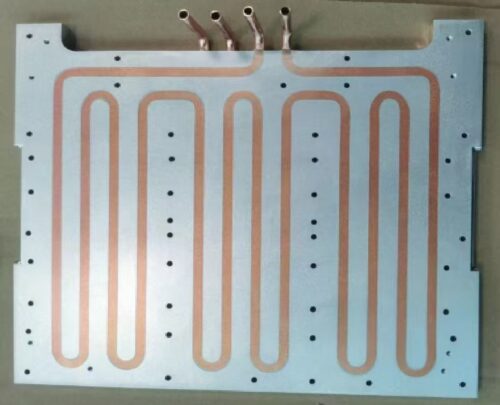

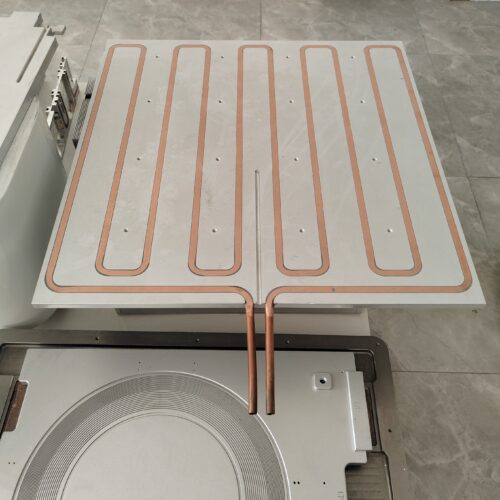

Advanced Copper Tube Plate Heat Exchanger: Optimal Efficiency for HVAC Systems

Introduction

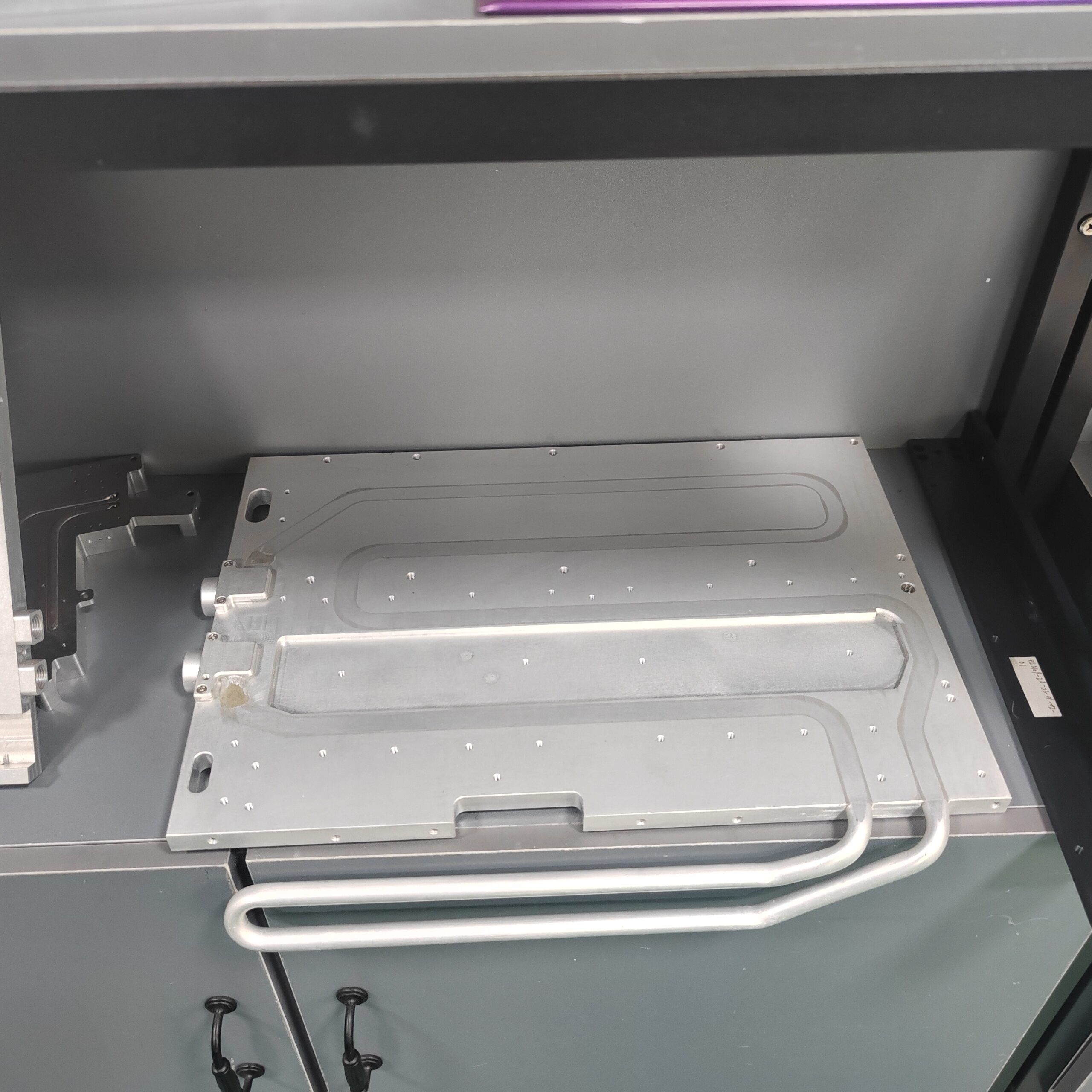

Elevate the performance of your heating, ventilation, and air conditioning (HVAC) systems with our Advanced Copper Tube Plate Heat Exchanger. Designed for precision and durability, this heat exchanger is a critical component for achieving maximum thermal efficiency and energy savings in various applications.

Detailed Product Description

Excellence in Thermal Exchange Technology

The Advanced Copper Tube Plate Heat Exchanger is a high-performance solution for efficient heat transfer between different media. It is an essential element in modern HVAC systems, designed to maintain optimal temperature levels and enhance overall system efficiency.

Key Features:

- High Thermal Conductivity:Copper tubes ensure rapid heat transfer, facilitating quick temperature adjustments.

- Robust Construction:Crafted from premium materials, these heat exchangers are built to last and withstand harsh operating conditions.

- Versatile Use:Suitable for a broad spectrum of applications, from residential HVAC to large-scale industrial processes.

- Low Maintenance:Engineered for ease of cleaning and maintenance, minimizing downtime and extending the lifespan of the equipment.

- Energy Efficiency:Contributes to significant energy savings by optimizing heat recovery and reducing the load on HVAC systems.

Why Choose Our Advanced Copper Tube Plate Heat Exchanger?

Enhanced System Performance: Our heat exchanger boosts the efficiency of your HVAC systems, leading to lower energy consumption and reduced operating costs.

Extended Equipment Lifespan: By maintaining ideal operating temperatures, our heat exchanger helps prolong the life of your HVAC systems and related equipment.

SEO Focused Description:

Maximize the efficiency of your HVAC systems with our Advanced Copper Tube Plate Heat Exchanger, designed for superior heat transfer and energy efficiency. Ideal for heating, cooling, and refrigeration systems, this heat exchanger ensures rapid temperature adjustments and durable operation. Choose our heat exchanger for easy maintenance, extended equipment life, and enhanced system performance.

Keywords: Copper Tube Plate Heat Exchanger, HVAC Efficiency, Thermal Exchange Technology, Heat Transfer Solutions, Energy Saving HVAC.

Manufacturing Process:

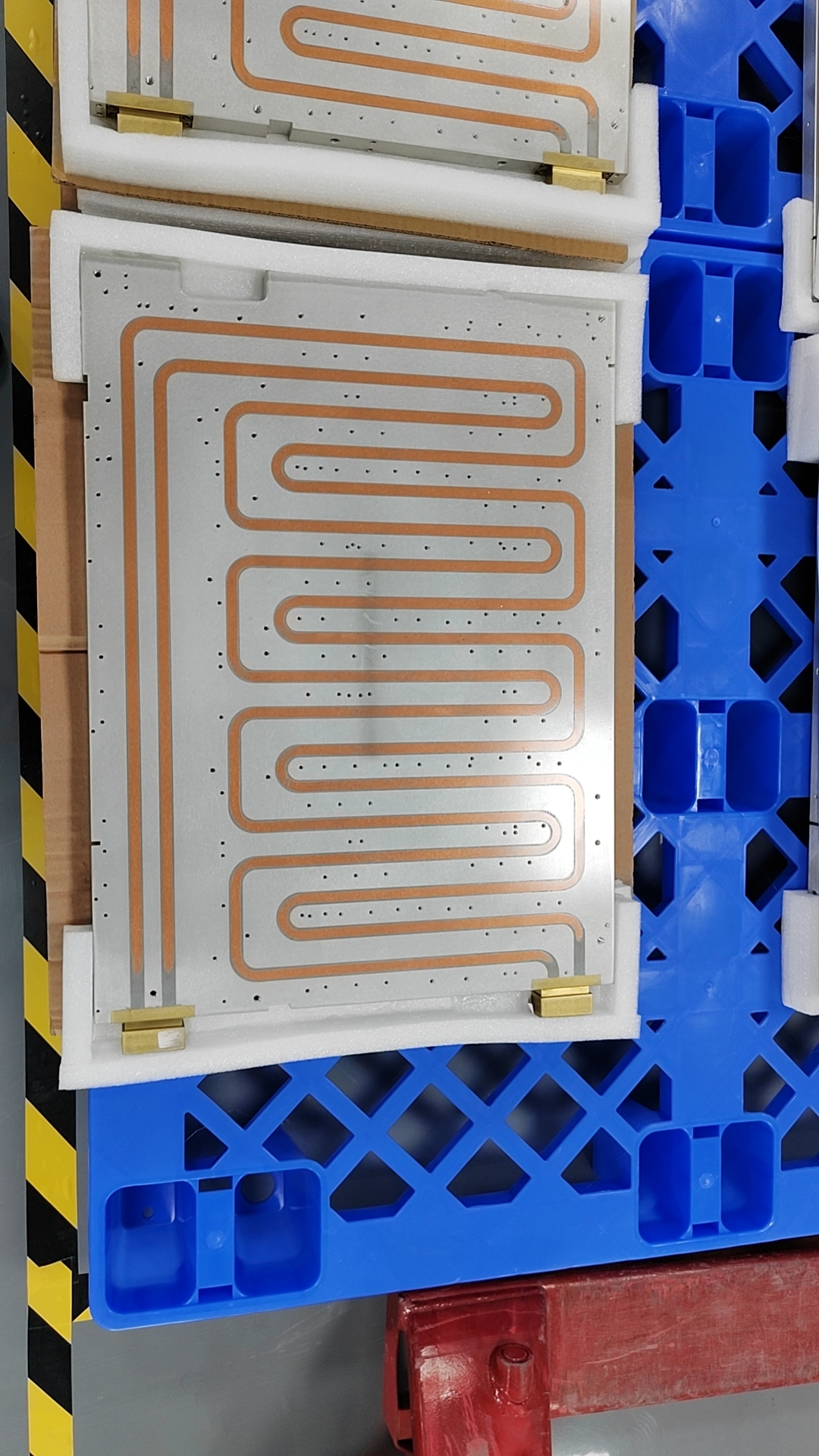

- Material Selection:High-quality copper tubes and durable metal plates are chosen for their exceptional thermal conductivity and resistance to corrosion.

- Tube Installation:Copper tubes are securely attached to metal plates through advanced welding or brazing techniques.

- Plate Processing:Metal plates are precision-cut and shaped to maximize the heat transfer surface area.

- Sealing:Advanced sealing techniques ensure no fluid leaks during operation.

- Assembly:The heat exchanger is assembled with precision to ensure optimal performance.

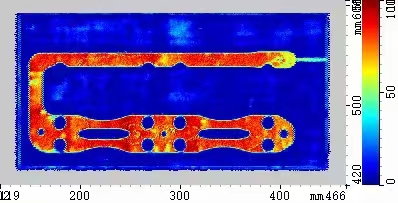

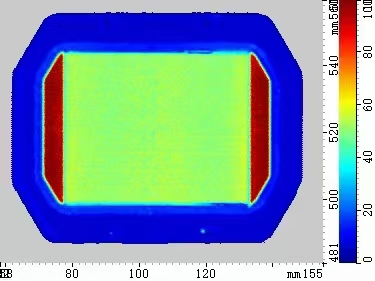

- Testing:Rigorous testing ensures the heat exchanger’s reliability and efficiency.

- Surface Treatment:Final surface treatments enhance durability and resistance to environmental factors.

评价

目前还没有评价