描述

Copper Tube Heat Exchanger: Precision-Engineered for HVAC Excellence

Introduction

Transform your HVAC system’s performance with our Copper Tube Heat Exchanger, a cutting-edge solution that promises unparalleled thermal efficiency and durability. Perfect for both commercial and residential applications, this heat exchanger is tailored to meet the rigorous demands of modern heating and cooling systems.

Detailed Product Description

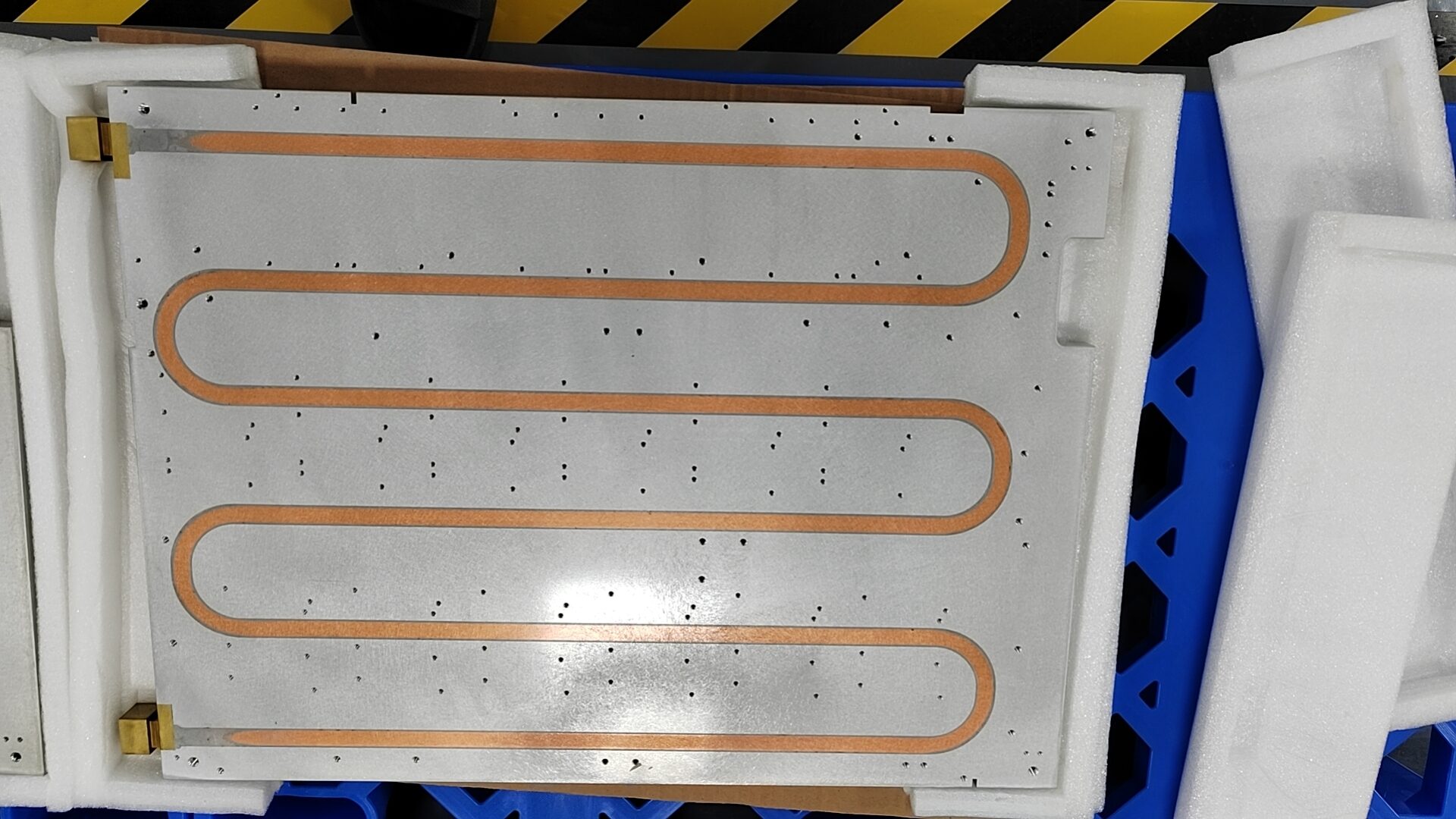

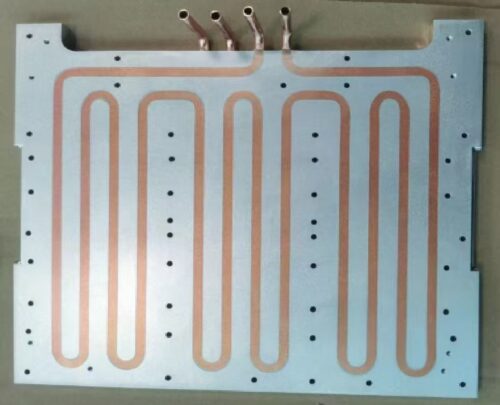

Innovation in Thermal Management

The Copper Tube Heat Exchanger is a precision-engineered device designed for superior heat transfer capabilities. It plays a pivotal role in HVAC systems, ensuring efficient temperature control and significant energy savings.

Key Features:

- Superior Heat Conductivity:Utilizing copper tubes renowned for their high thermal conductivity to ensure swift heat exchange.

- Sturdy Build:Constructed with premium-grade materials to ensure longevity and resistance to harsh conditions.

- Broad Applicability:Versatile enough for a wide range of applications, from small-scale residential systems to large industrial HVAC setups.

- Ease of Maintenance:Designed with user-friendly maintenance access to reduce service time and costs.

- Energy Conservation:Enhances energy efficiency by optimizing heat recovery processes within HVAC systems.

Why Select Our Copper Tube Heat Exchanger?

Boosted HVAC Performance: Our heat exchanger significantly improves HVAC system efficiency, leading to lower energy bills and operational costs.

Prolonged System Lifespan: Helps maintain ideal operating temperatures, thereby extending the lifespan of your HVAC equipment.

SEO Focused Description:

Achieve peak HVAC efficiency with our Copper Tube Heat Exchanger, expertly designed for top-tier heat transfer and energy conservation. Suited for a variety of heating, cooling, and refrigeration systems, this heat exchanger guarantees rapid temperature regulation and robust operation. Opt for our heat exchanger for simplified maintenance, extended equipment lifespan, and superior system performance.

Keywords: Copper Tube Heat Exchanger, HVAC System Efficiency, Heat Transfer Device, Energy Conservation HVAC, HVAC Maintenance.

Manufacturing Process:

- Material Procurement:Selecting top-quality copper tubes and metal plates for optimal thermal performance and durability.

- Tube Integration:Attaching copper tubes to metal plates using reliable welding or brazing methods.

- Plate Fabrication:Cutting and shaping metal plates with precision to maximize heat transfer surface area.

- Seal Assurance:Implementing superior sealing to prevent any operational fluid leaks.

- Unit Assembly:Assembling the heat exchanger with meticulous care to guarantee peak performance.

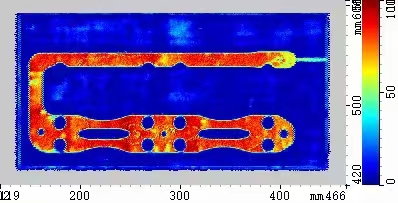

- Quality Assurance:Conducting thorough testing to ensure reliability and efficiency.

- Surface Finishing:Applying final surface treatments for enhanced durability against environmental factors.

评价

目前还没有评价