描述

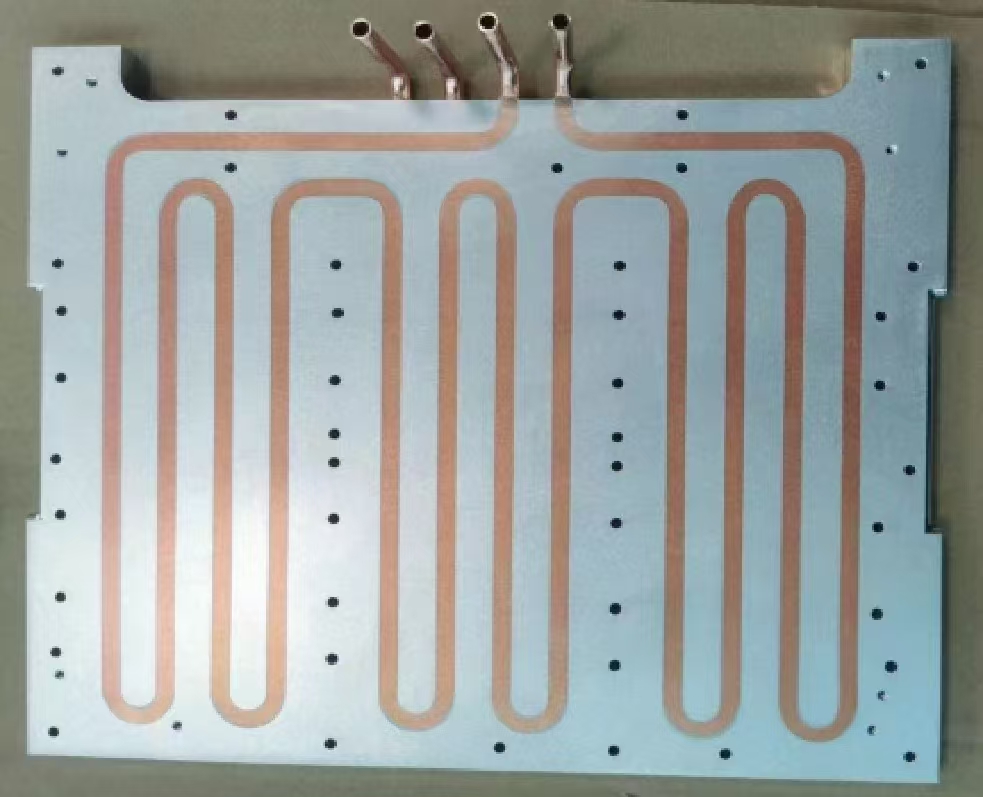

Efficient Copper Tube Heat Exchanger for Advanced HVAC Applications

Introduction

Step into the future of HVAC technology with our Efficient Copper Tube Heat Exchanger, a product that exemplifies cutting-edge design and superior performance. Engineered to cater to the evolving needs of heating and cooling systems, this heat exchanger is your key to energy-efficient and sustainable operation.

Detailed Product Description

Revolutionizing Thermal Efficiency

The Efficient Copper Tube Heat Exchanger is a meticulously designed piece of equipment that stands out for its high-performance heat transfer capabilities. It is a critical component in the quest for optimal temperature management in HVAC systems.

Key Features:

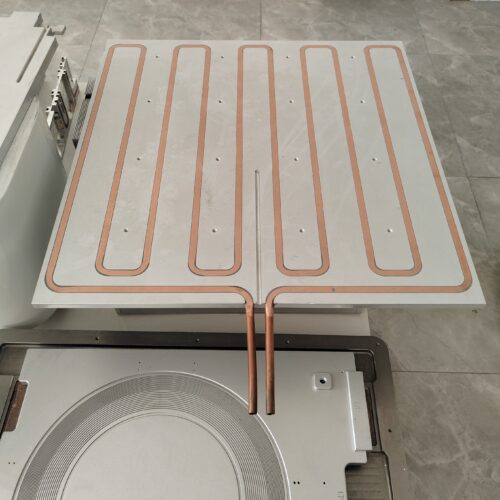

- Exceptional Thermal Conductivity:Features copper tubes known for rapid heat transfer, facilitating prompt thermal equilibrium.

- Durable Construction:Made with high-grade materials to ensure resilience and longevity even in demanding environments.

- Versatile Compatibility:Suitable for a diverse array of applications, from residential to large-scale commercial HVAC systems.

- User-Friendly Maintenance:Constructed for easy access and servicing to minimize downtime and maintenance costs.

- Enhanced Energy Efficiency:Contributes to energy conservation by enhancing heat recovery within HVAC systems.

Why Choose Our Efficient Copper Tube Heat Exchanger?

Optimized HVAC Performance: Our heat exchanger significantly enhances HVAC system performance, leading to reduced energy consumption and lower operational costs.

Extended System Lifespan: Helps maintain ideal operating temperatures, thereby extending the lifespan of your HVAC equipment.

SEO Focused Description:

Maximize your HVAC system’s potential with our Efficient Copper Tube Heat Exchanger, meticulously engineered for superior heat transfer and energy efficiency. Ideal for a broad spectrum of heating, cooling, and refrigeration systems, this heat exchanger ensures swift temperature control and durable operation. Select our heat exchanger for hassle-free maintenance, extended equipment lifespan, and enhanced system performance.

Keywords: Efficient Copper Tube Heat Exchanger, HVAC Performance Enhancement, Thermal Efficiency, HVAC Energy Conservation, Sustainable HVAC Solutions.

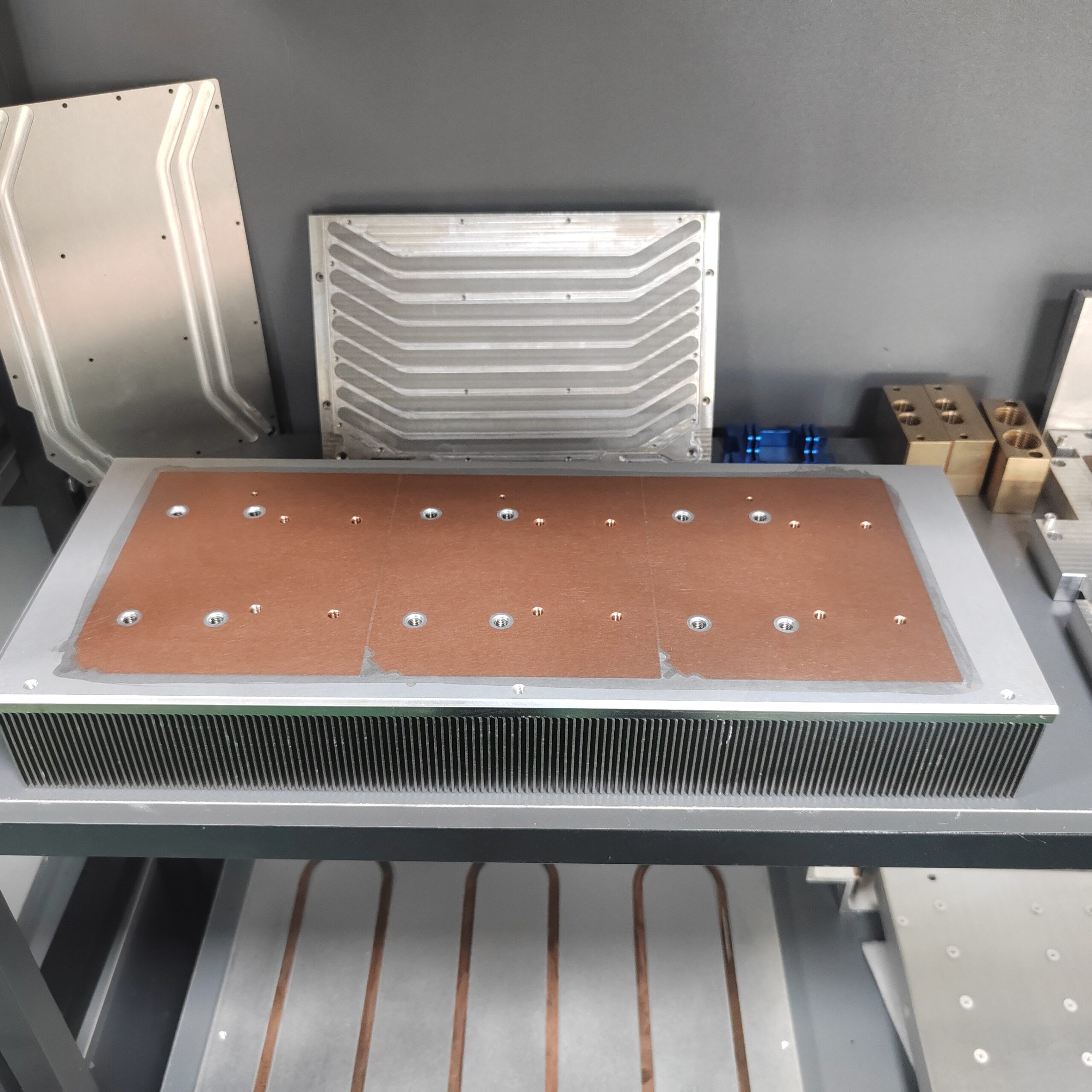

Manufacturing Process:

- Material Selection:Utilizing premium copper tubes and robust metal plates for their outstanding thermal properties and durability.

- Precision Tube Installation:Copper tubes are meticulously attached to metal plates using reliable welding or brazing techniques.

- Advanced Plate Machining:Metal plates are precisely cut and shaped to maximize the heat transfer surface area.

- Sealing Technology:Employing advanced sealing methods to prevent any operational fluid leaks.

- Careful Assembly:The heat exchanger is assembled with precision to ensure optimal performance.

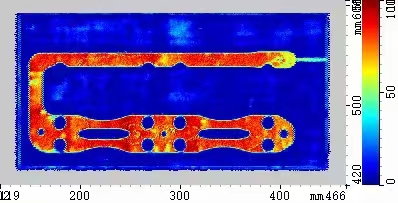

- Comprehensive Testing:Rigorous testing is conducted to ensure the heat exchanger’s reliability and efficiency.

- Durable Surface Treatment:Applying final surface treatments for enhanced resistance to environmental factors.

评价

目前还没有评价