描述

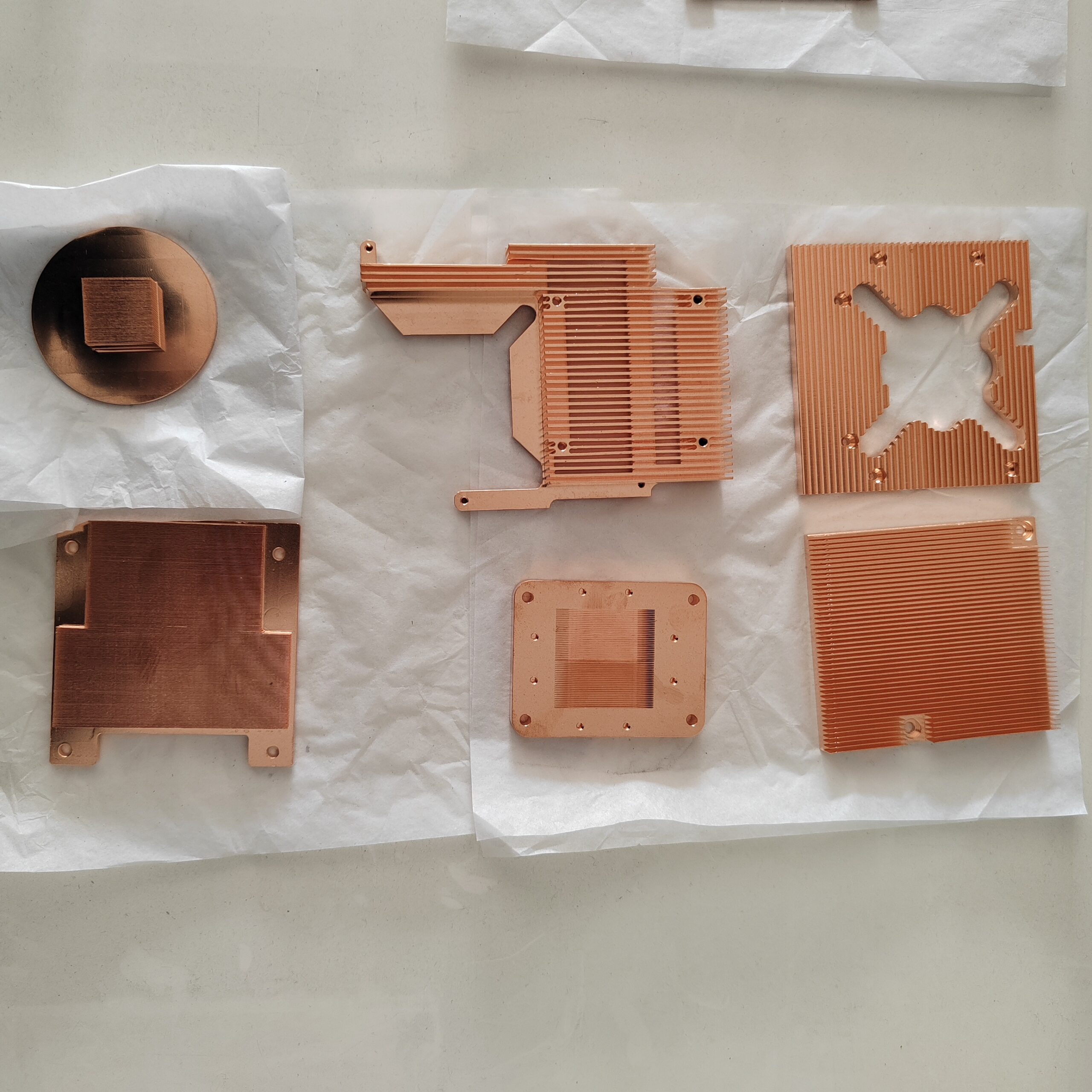

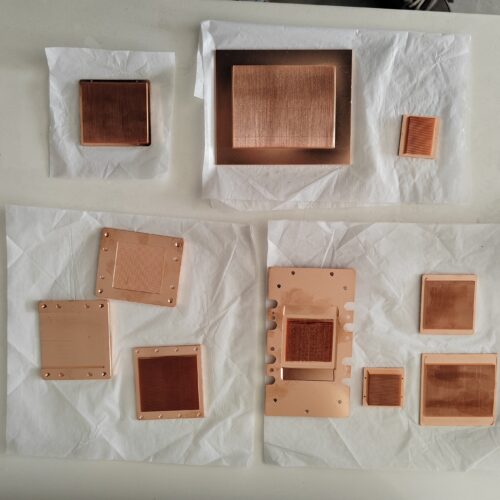

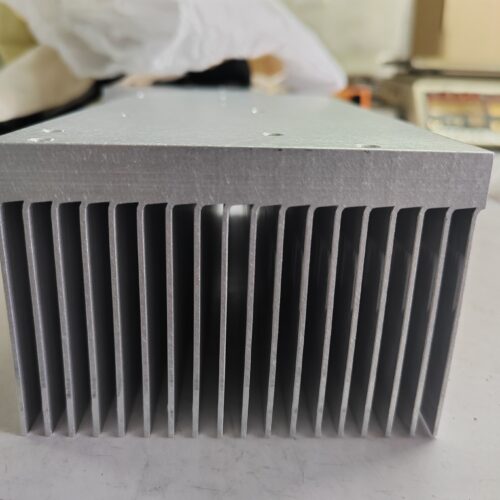

Copper and Aluminum Efficient Heat Sinks for Computer Servers and Electronics Cooling Solutions

Enhance your device’s performance with our top-of-the-line Copper and Aluminum Efficient Heat Sinks. Designed for computer servers, electronics cooling, and thermal management solutions, these heat sinks guarantee optimal heat dissipation and durability.

The Ultimate Cooling Solution: Copper and Aluminum Heat Sinks

Our Copper and Aluminum Efficient Heat Sinks are the pinnacle of thermal management technology, providing unmatched heat dissipation for computer servers, high-performance computers, and a variety of electronics.

Key Features:

- Superior Heat Transfer: Available in both copper and aluminum, our heat sinks offer high thermal conductivity for efficient heat transfer.

- Advanced Fin Design: The intricate fin design increases surface area, promoting faster heat dissipation and maintaining device performance.

- Robust Construction: Made from durable materials, our heat sinks are built to last, ensuring long-term reliability and performance.

- Lightweight Construction: Despite their strength, our heat sinks are lightweight, suitable for a wide range of applications without adding unnecessary weight.

- Simple Installation: With user-friendly mounting holes, our heat sinks are easy to install, saving you time and effort.

Applications:

Our heat sinks are ideal for:

- Computer Servers: Keep your server rooms cool and efficient.

- High-Performance Computers: Ensure your gaming or workstation PCs maintain optimal temperatures.

- Electronics Cooling: Perfect for power amplifiers, industrial machinery, and audio/video equipment.

Manufacturing Process:

- Material Selection: We choose high-quality copper and aluminum for their excellent thermal properties.

- Precision Extrusion: The materials are extruded with precision to achieve the desired shape and dimensions.

- Cutting and Shaping: The extruded materials are cut and shaped to fit your specific cooling needs.

- Surface Treatment: We apply advanced surface treatments to enhance corrosion resistance and improve aesthetics.

SEO Content

In the fast-paced world of electronics, managing heat is crucial for the performance and longevity of your devices. Our Copper and Aluminum Efficient Heat Sinks are designed to tackle this challenge head-on, offering a reliable solution for thermal management across various applications. Whether you’re managing a server room, upgrading your gaming PC, or cooling industrial machinery, our heat sinks are the perfect choice.

By investing in our heat sinks, you’re not just buying a cooling solution; you’re investing in the future of your devices. Our products are designed to keep your electronics running smoothly, reducing the risk of overheating, and extending their operational life. With our heat sinks, you can ensure that your devices stay cool, efficient, and reliable, no matter the workload.

Keywords

- Copper heat sinks

- Aluminum heat sinks

- Efficient heat dissipation

- Computer server cooling

- Electronics cooling solutions

- Thermal management technology

- High-performance computer cooling

- Industrial machinery cooling

- Audio/video equipment heat sinks

- Power amplifier heat sinks

评价

目前还没有评价