描述

Why Our Soft Copper Busbars Stand Out

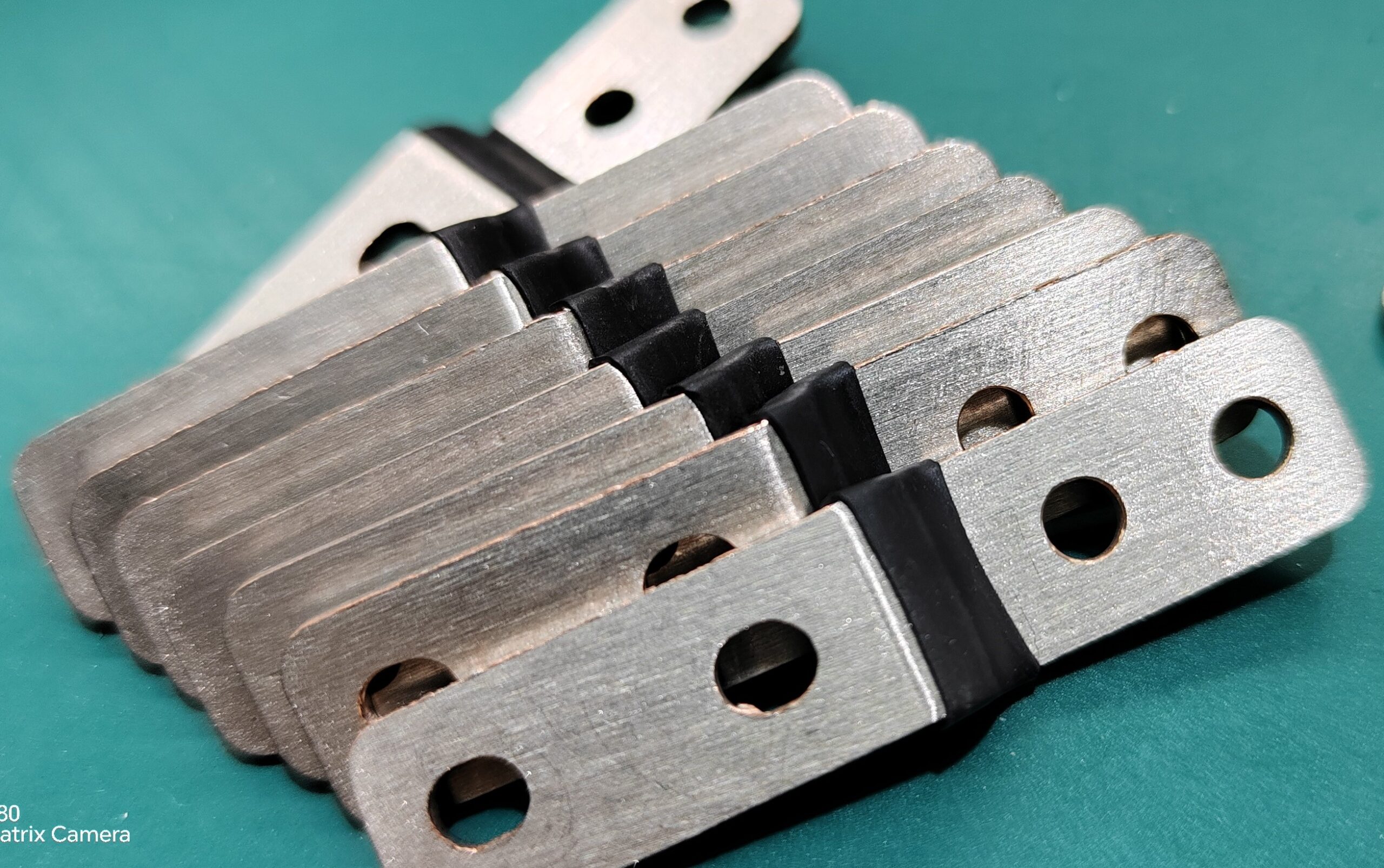

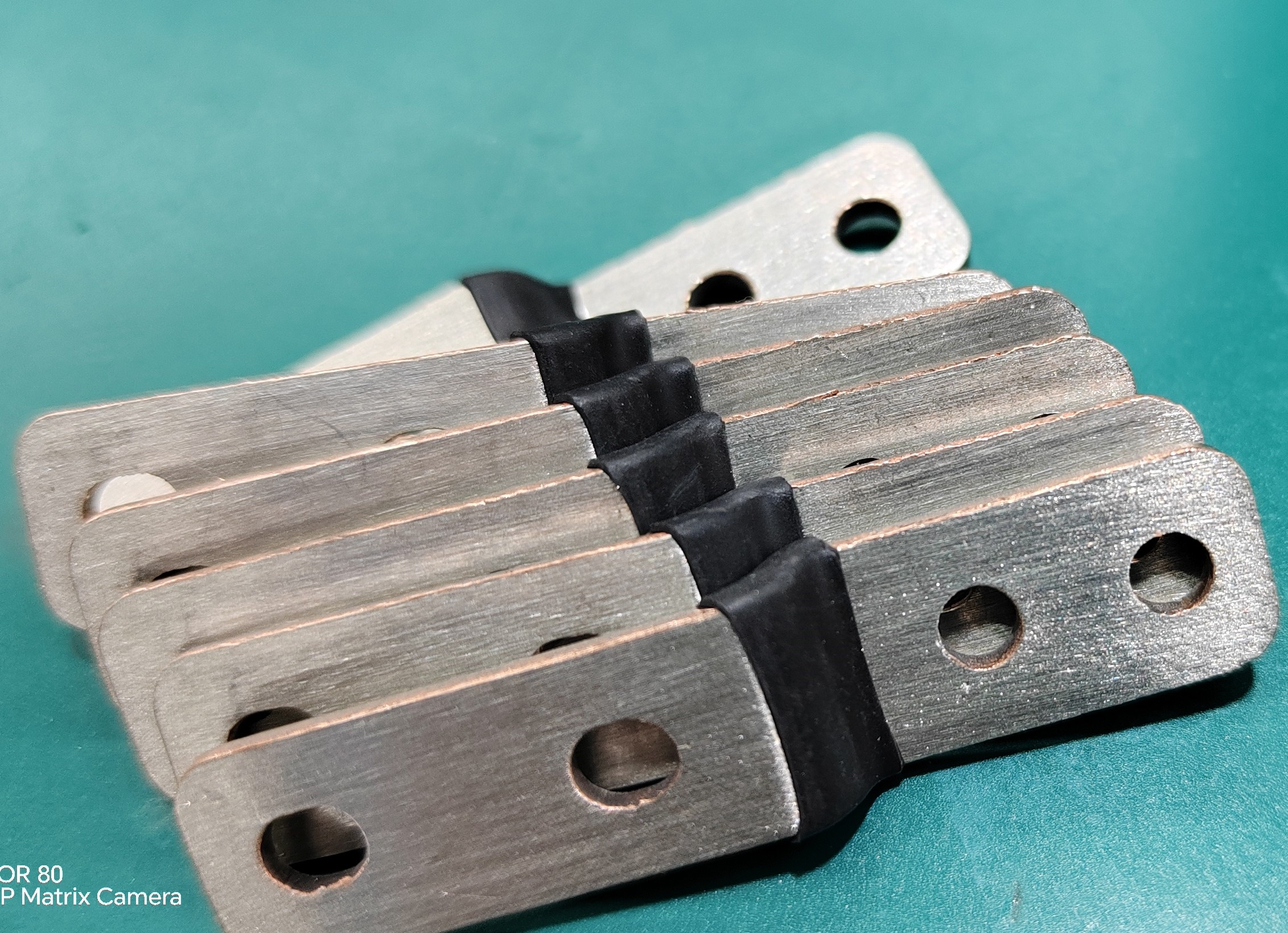

Our Soft Copper Busbars are crafted to meet the demands of modern power distribution systems. They offer a unique combination of high conductivity, flexibility, and durability, making them indispensable in various applications。

Key Features:

- Superior Conductivity: Made from high-quality copper, ensuring minimal energy loss and optimal performance.

- Flexibility: Designed to bend and twist, accommodating complex installation requirements effortlessly.

- Durability: Built to withstand harsh conditions, providing long-term reliability and reducing maintenance needs.

- Easy Installation: User-friendly design simplifies the installation process, saving time and effort。

Applications:

Our Soft Copper Busbars are perfect for:

- Industrial Machinery: Ensure efficient power distribution in heavy machinery.

- Electrical Installations: Ideal for use in electrical panels and switchboards.

- Automotive and Electric Vehicles: Manage power flow in battery systems efficiently.

- Renewable Energy Systems: Contribute to efficient energy management in solar and wind farms。

Manufacturing Process:

- Material Selection: We choose high-quality copper for its superior conductivity and durability.

- Precision Extrusion: The copper is extruded into the desired shape, ensuring precision and consistency.

- Cutting and Shaping: The extruded copper is cut and shaped to meet your specific requirements.

- Surface Treatment: We apply advanced treatments to enhance durability and resist corrosion。

- Quality Assurance: Each busbar undergoes rigorous testing to ensure it meets our high standards for quality and performance。

评价

目前还没有评价